Composite Rods

OUR BRAND – JITEC

Non-metallic composite load-bearing rods, braided, made of E-glass fiber and a thermosetting resin.

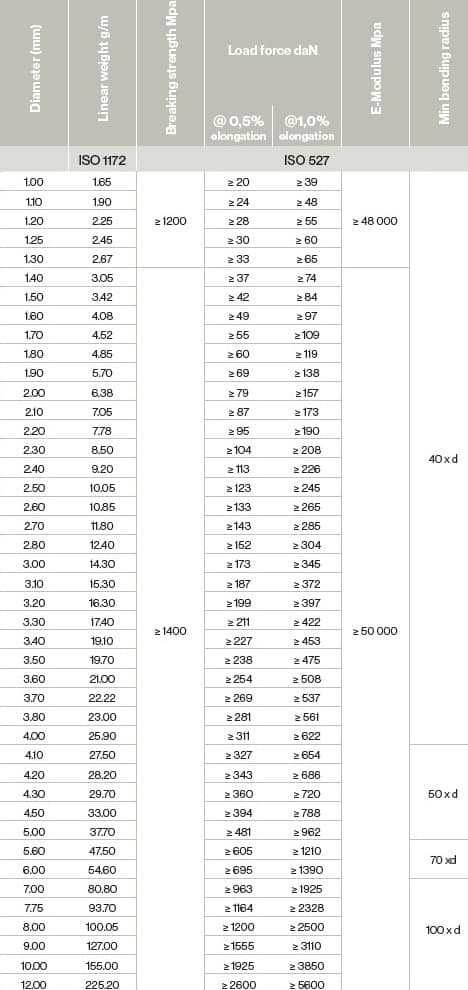

Available in a wide range of diameters from 1 mm to 11 mm.

The process involves impregnating continuous fibers by dipping them into a thermosetting resin.

The impregnated strands are then assembled, shaped, and calibrated.

Final curing is carried out by thermal polymerization before winding onto wooden reels.

Fields of application: telecommunications – reinforcement of optical fiber cables for traction, bending, and torsion.

Manufacturing technology

Pultrusion & Impregnation

Continuous fibers are dipped in a thermosetting resin, then assembled, calibrated, and shaped before being cured through thermal polymerization.

The FRP pultrusion process is specifically used for manufacturing composite rods for cable reinforcement.

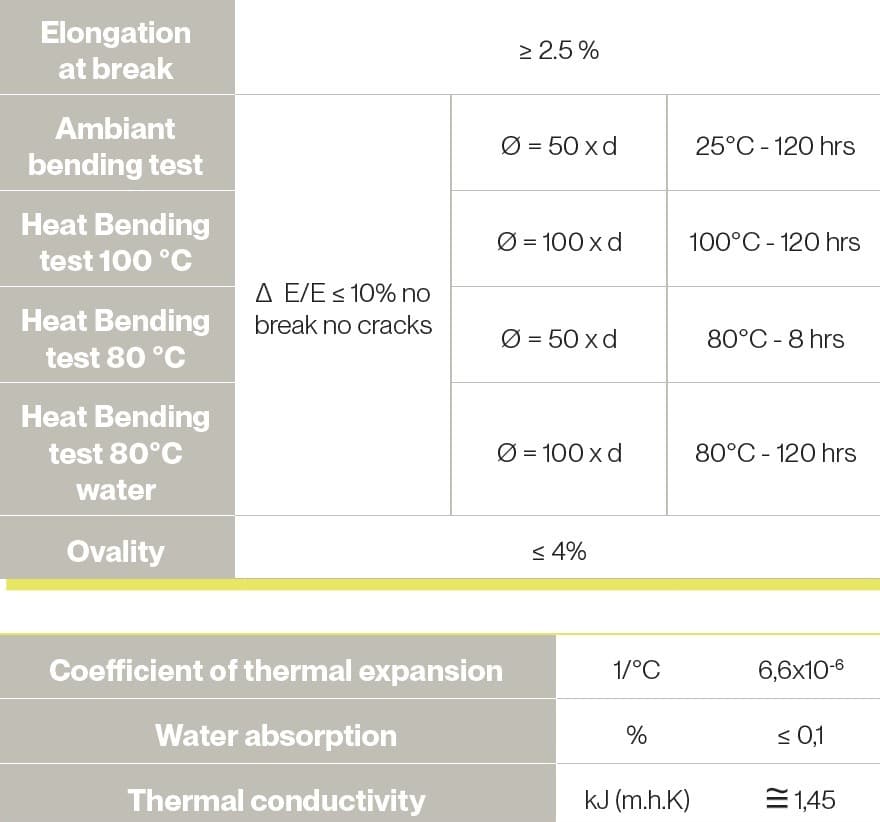

Mechanical & Physical Properties

Lightweight, with a typical density around 1.9.

High tensile strength, lower elongation compared to steel.

Dimensional rigidity suitable for integration into optical cables.

Non-magnetic, corrosion-resistant, electrically insulating — ideal for environments sensitive to interference.

Prototypes

We can produce calibrated samples and conduct precise tests according to some of your specifications.