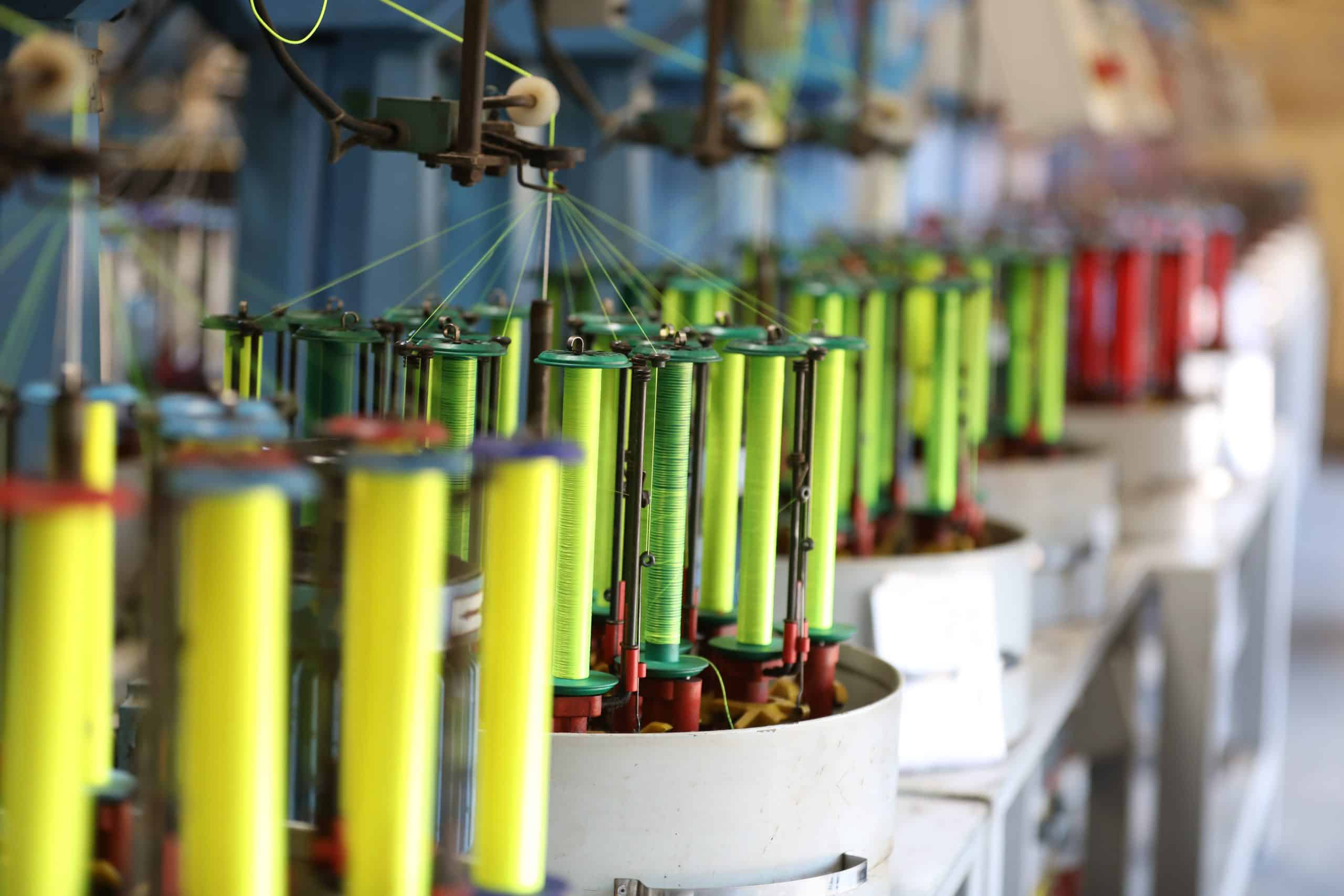

Fibers and Composites

A project?

Cousin® develops your industrial projects

A high-performance industrial textile cable project?

Our design office develops your product with you.

Our process

Submit your request using our contact form:

- Requirement

- End use

- Environment in which your product will be used

- Desired technical characteristics

- Desired length and diameter

- COUSIN® brand or white label

Our design office will then examine the feasibility of your request.

All technical and mechanical criteria are analyzed, including raw materials, assembly, construction, processing, finishing, and packaging.

If development is possible, the sales team will send you a quote and delivery time.

After approval of the quote and technical file, a prototype can be tested before being sent to you. We can have your product certified by the organization of your choice.

All our products undergo rigorous laboratory testing: breaking strength, impact strength, elongation, flexibility, knotability, sheath slippage, water shrinkage, etc.

All testing complies with the various ISO regulations and European standards in force.

Additional tests can be carried out on request.

Your request is ready for industrialization.

We are committed to meeting the deadline.

The group

COUSIN® industrie française depuis 1848

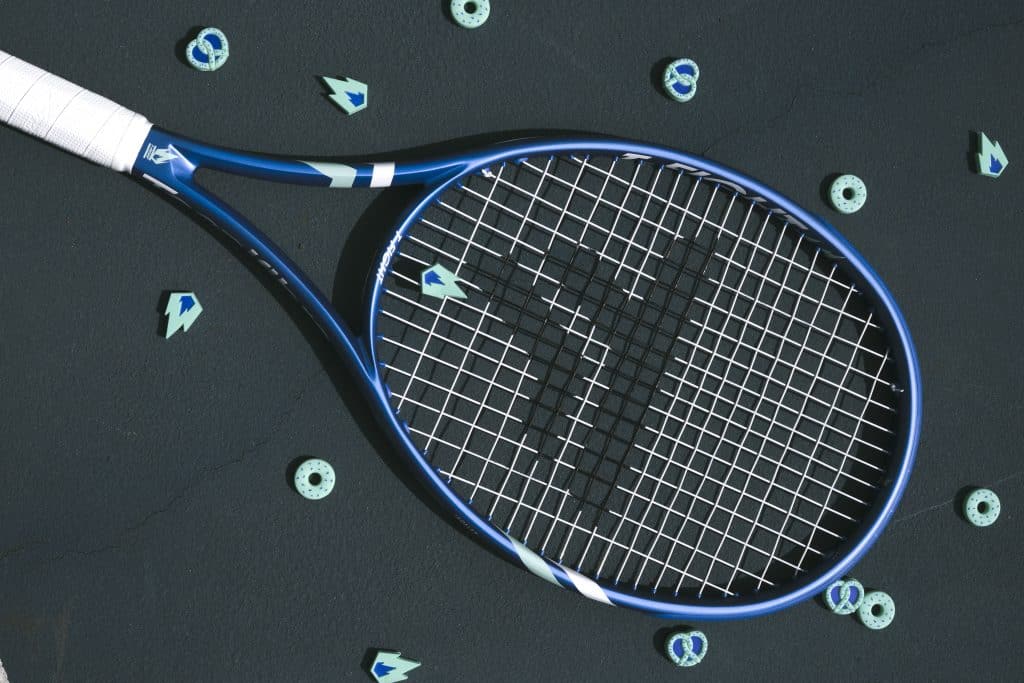

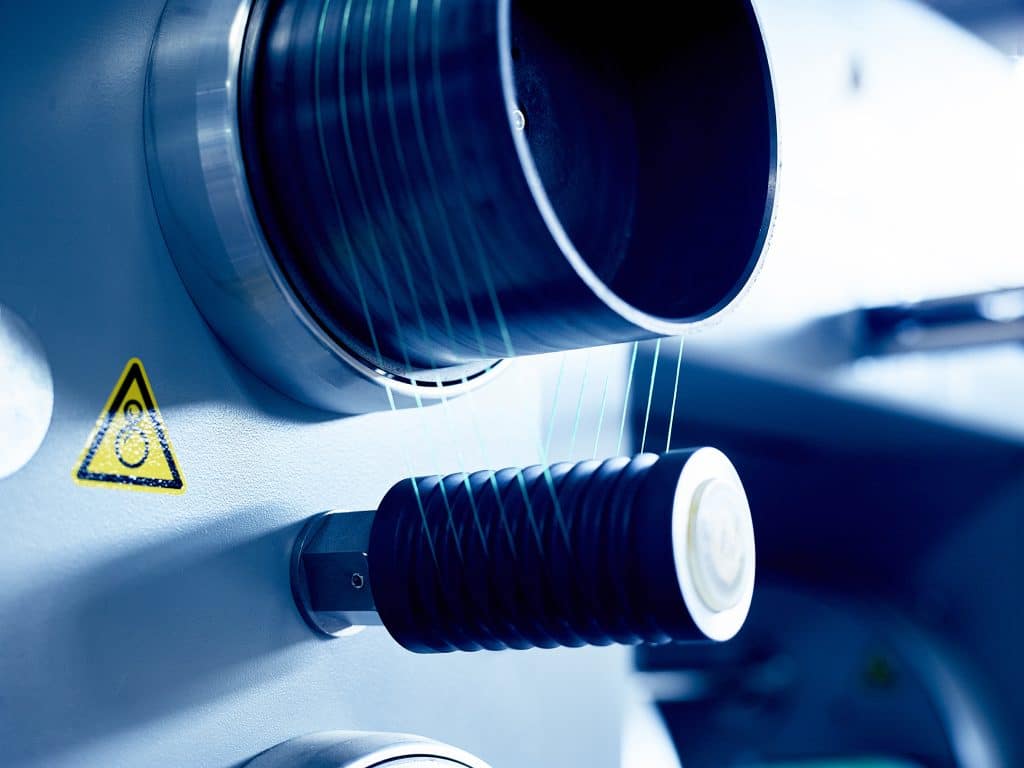

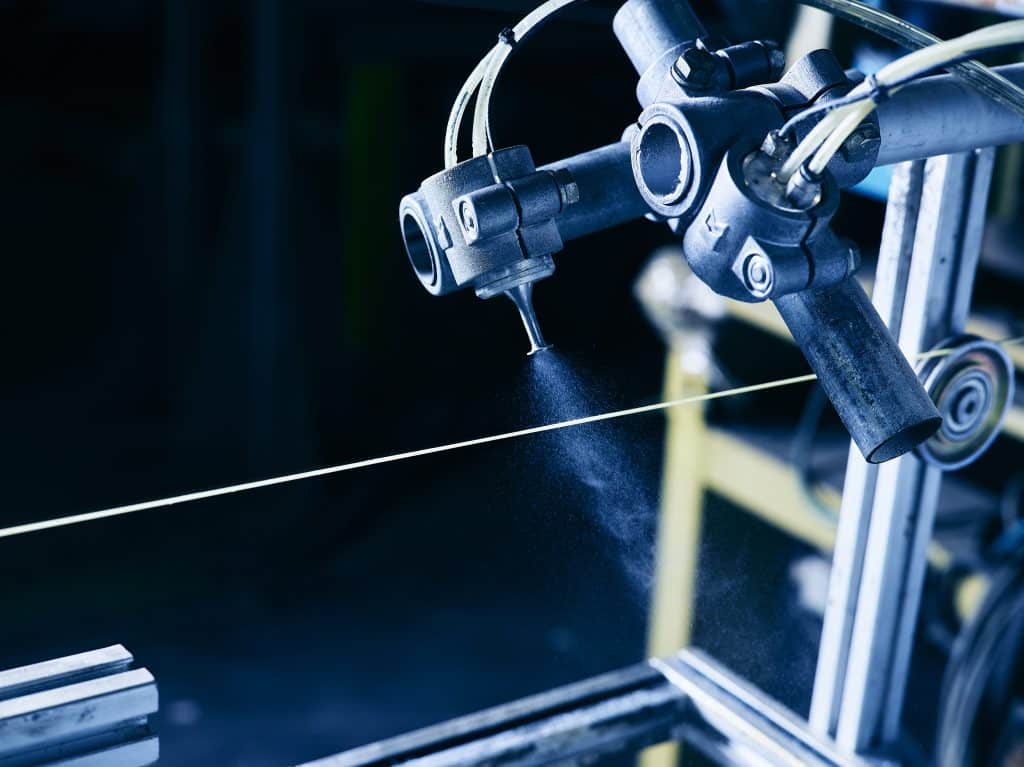

COUSIN® se positionne depuis sa création en 1848 comme expert de la fibre et de la corde technique façonnées pour des usages intensifs. Dès 1990 COUSIN filialise ses activités. Le groupe s'expertise en tant que fabricant de cordages pour le sport et les loisirs (kitesurf, nautisme, escalade ...), pour les travaux de grande hauteur EPI, pour l'industrie ou encore la défense. Le groupe COUSIN® devient également un acteur majeur dans la fabrication de fibres hautes performances et composites renforcés pour tous types d'industries et dédie une partie de sa production aux cordages de raquettes de tennis et de squash. Les derniers investissements technologiques placent de groupe sur les plus grands marchés internationaux.

In a few figures

- 177 Années d'expérience

- 160 Collaborateurs

- 60 Pays livrés

- 300 000 000 Mètres de produits finis par an