Polymer melt spinning

OUR BRAND – YARNTEC

Melt spinning, in mono- or bi-component, monofilament, and multifilament polymers, enabling the processing of all thermoplastic polymers with transformation temperatures up to 400 °C (PA11 / PA12 / RPA6 / PC / PEI / TPE / PPS / PEEK).

Fields of application : sports and leisure, aeronautics, rail, technical textiles, construction, and more

Autres produits sur demande

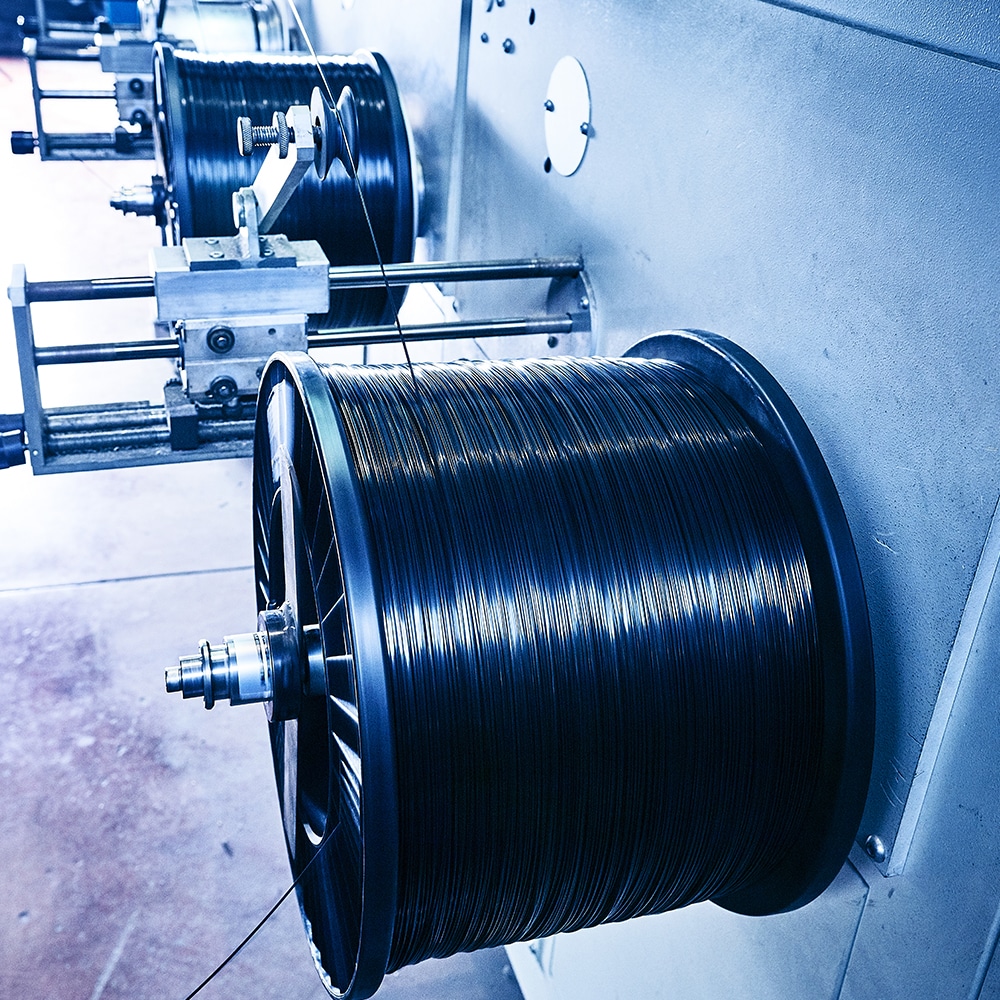

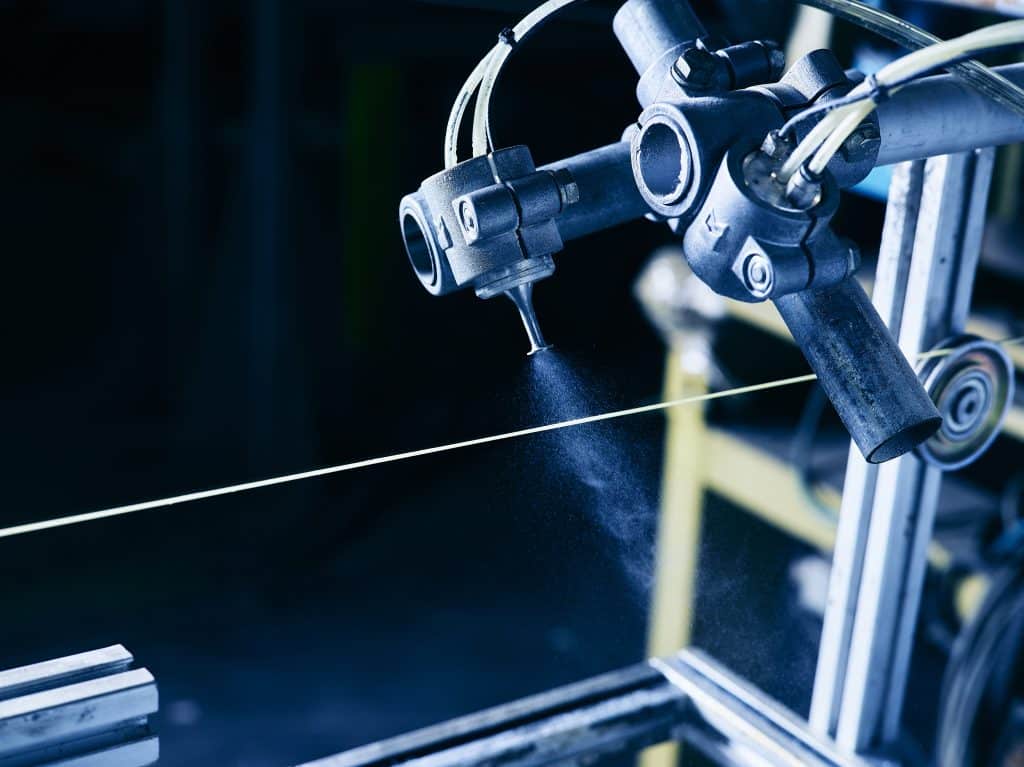

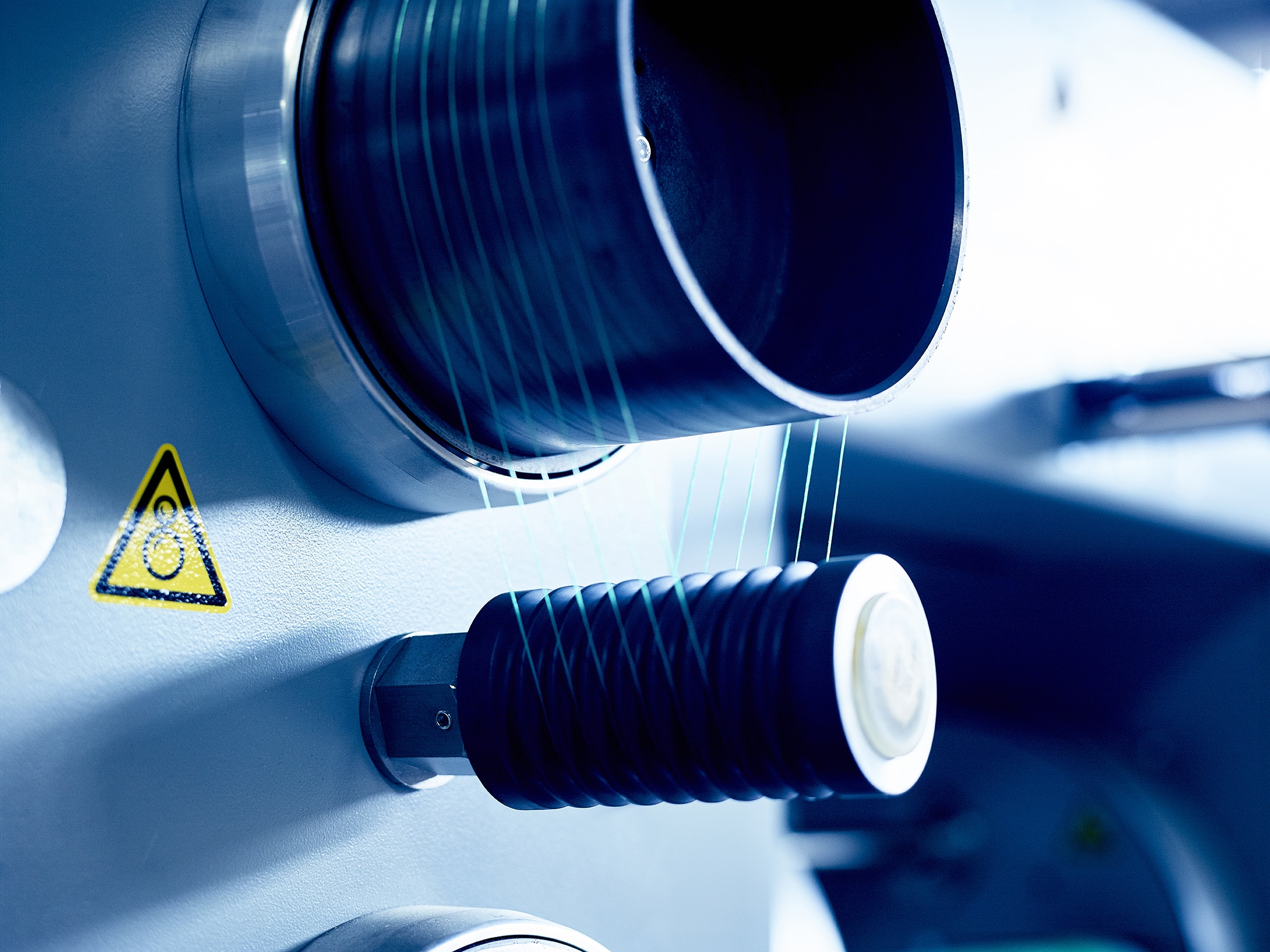

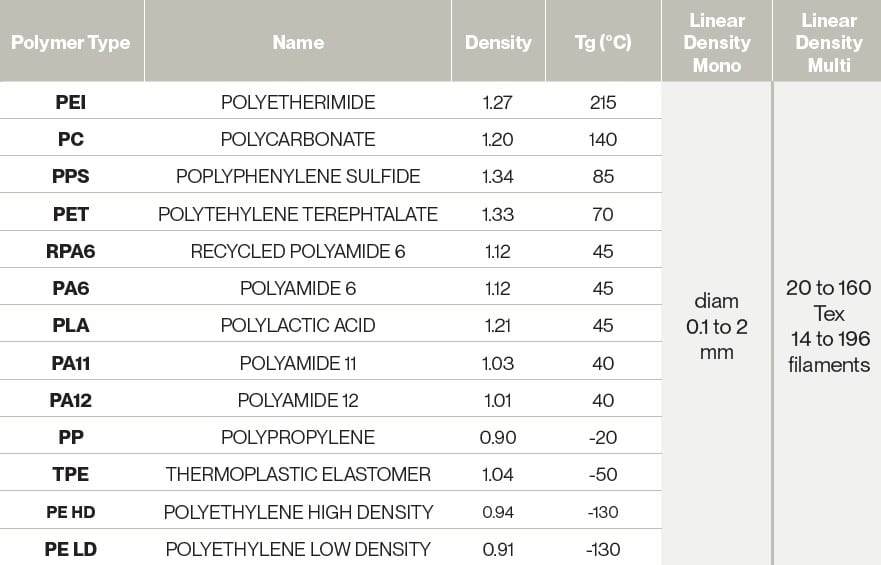

Manufacturing technology

Melt spinning, in mono- or bi-component form, is suitable for thermoplastic polymers that can be processed up to 400 °C, such as PA11, PA12, RPA6, PC, PEI, TPE, PPS, and PEEK, among others.

These polymers are extruded into monofilaments or multifilaments, depending on the application requirements. Extrusion is carried out through multi-cavity dies, enabling the production of uniform filaments with controlled diameters. The orientation of macromolecular chains through hot drawing achieves stretch ratios of up to 500%, providing the filaments with controlled mechanical properties such as tenacity, stiffness, resilience, tensile strength, and abrasion resistance.

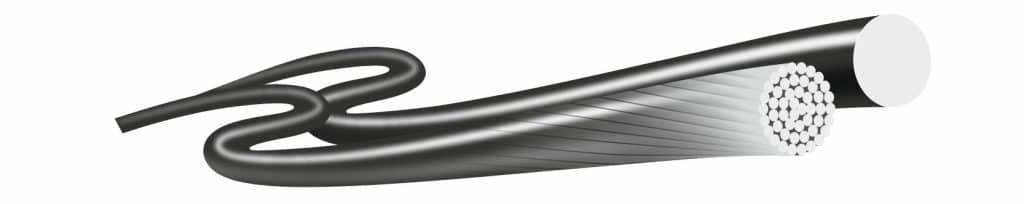

RACKET STRINGS

It is using this same process that we manufacture tennis and squash racket strings, both monofilament and multifilament, notably for brands such as Tecnifibre and Wilson.