Technologies

Extrusion (monofilament, multifilament)

The company’s expertise in extrusion coating is a major strength. Our extrusion capabilities now include functionalizing a wide range of monofilament and multifilament yarns.

This technology is applied in a variety of sectors, including industry, sports and leisure, medical, construction, automotive, railway, and aerospace.

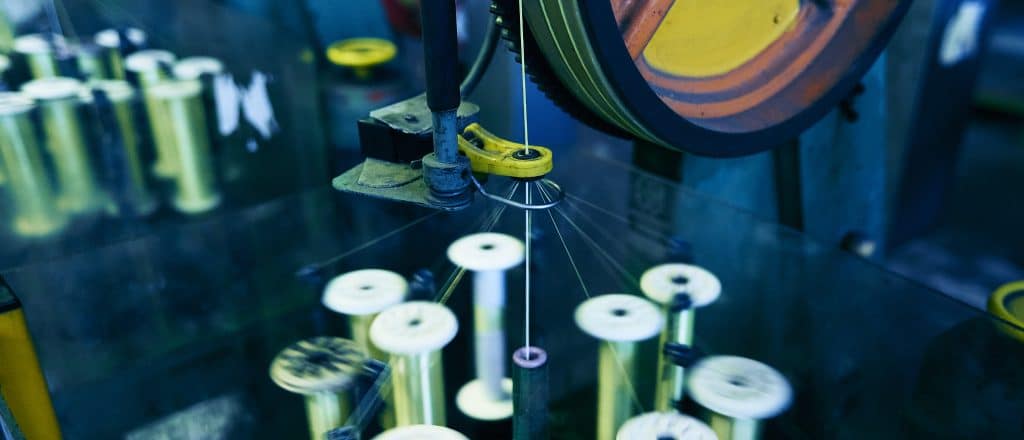

FIBER ASSEMBLY / COMMINGLING

Thermoplastic hybrid yarns are increasingly popular in the composites industry due to their combination of mechanical strength and ease of processing. They are composed of a blend of reinforcing fibers (glass, carbon, aramid, etc.) and thermoplastic matrices such as polyamide 11 (PA11), polycarbonate (PC), polyphenylene sulfide (PPS), polyetherimide (PEI), or polyether ether ketone (PEEK).

The integration of two different materials into a single yarn made from continuous filaments opens up new possibilities and applications, through processes such as knitting, braiding, weaving, and even developments using TFP (Tailored Fiber Placement) technology. These yarns enable the direct production of composite materials without the need for an additional resin impregnation step.

Pultrusion

COUSIN® has developed a unique manufacturing process for FRP (Fibre Reinforced Products), primarily intended for reinforcing optical fiber cables.

These composite rods (reinforced with glass, aramid, or carbon) can also replace steel in many applications while being lighter, non-magnetic, and corrosion-resistant

IMPREGNATION/COATING

The coating workshop is equipped with numerous impregnation lines for processing textile strands individually or in bundles.

Regardless of the yarn type (glass, carbon, aramid, polyester, or high-molecular-weight polyethylene) a wide range of resins can be used for impregnation: polyurethane, acrylic, silicone, PVC, and more.

The desired properties may include: abrasion resistance, improved UV resistance, fire-retardant properties, etc

BRAIDING

We also specialize in braiding technologies, with the possibility of resin impregnation.