Group

Based in northern France, the COUSIN® Group specializes in manufacturing reinforced fibers, ropes, and innovative textile braids. With nearly 180 years of experience, COUSIN® is a leading technical and professional expert in both the sports and industrial sectors.

Recent technological investments have placed the group in the major international markets. COUSIN® reinvests roughly 5% of its turnover in Research and Development each year. Eight engineers, along with state-of-the-art equipment, enable the group to meet even the most demanding technical requirements

Manufacturer of innovative textile braids for visible performance

Since 1848, the COUSIN® Group has specialized in processing fibers, mostly synthetic, through twisting, cabling, braiding, and impregnation. Its professional clientele spans a wide range of fields including sports (water sports, climbing, caving, hiking, mountaineering, paragliding, kitesurfing, etc.), safety (working at height, rescue, handling, events, etc.), industrial applications (offshore, lifting, automotive), and the military. COUSIN® is recognized as a benchmark in the rope market.

EXPERT IN FIBER REINFORCEMENT

Using polymer extrusion spinning, COUSIN® produces thousands of kilometers of non-metallic composite rods each year. These braided industrial reinforcement rods are made of E-glass fiber and a curable thermoplastic resin.

They can be sheathed for a variety of applications.

COUSIN® employs highly technical processes to enhance the performance of various fibers. This includes advanced technologies such as polymer extrusion spinning (PA11/PA12/RPA6/PC/PEI/TPE/PPS/PEEK), coating, co-extrusion, assembly, braiding, and over-braiding, applied across industries including automotive, rail, aerospace, medical, construction, sports, and leisure.

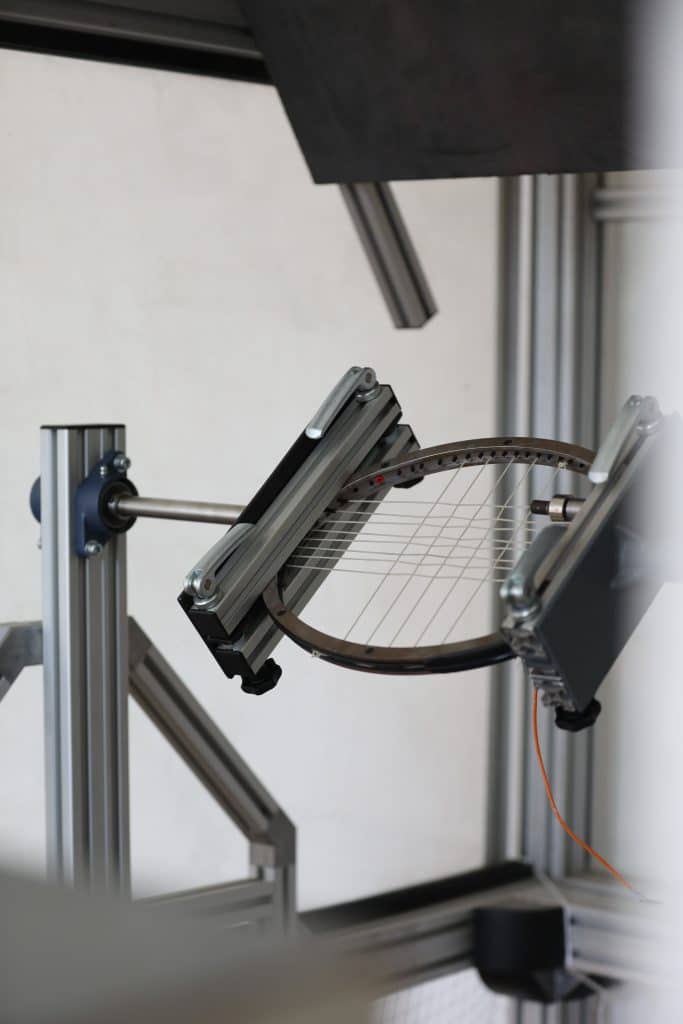

MANUFACTURER OF THE STRINGS FOR TOMORROW’S RACKETS

Thanks to its broad expertise, COUSIN® is one of Europe’s leading manufacturers of tennis and squash strings.

COUSIN® has developed two high-performance manufacturing processes, establishing the group as a leading manufacturer of racket strings in Europe.

The “multifilament” process relies on bicomponent melt spinning, enabling the use of all thermoplastic polymers that can be processed below 400°C.

The more exclusive “monofilament” process is based on the extrusion and controlled stretching of polymers.

This unique expertise has attracted leading brands. Today, 100% of Tecnifibre tennis and squash strings are manufactured in our facilities, along with a significant share of the Wilson range.

The latest addition is the Soft Razor string, used by top players such as Daniil Medvedev and Iga Świątek.

High standards of quality

Group holds ISO 9001, 14001, and 45001 certifications, reflecting its commitment to quality, environmental management, and workplace safety. This is achieved through structured organization, optimized processes, and a strong focus on resource conservation while ensuring employee well-being and product quality for customers.

The Group’s expertise has also been recognized with the Entreprise du Patrimoine Vivant (EPV) label, awarded by the French government to companies with exceptional craftsmanship and industrial skill. This prestigious label acknowledges decades of technical mastery, innovation, and knowledge transfer.

Finally, the Group’s environmental commitment is reinforced by the Coq Vert label, awarded by Bpifrance and ADEME, which brings together pioneering companies in the ecological transition. This label underscores a tangible commitment to reducing carbon footprints and promoting sustainable practices in both production and management.

Following an initial carbon assessment, an Impact Committee of about ten employees was established to accelerate sustainable projects.