Winching

Filter by usage

A project?

Cousin® develops your industrial projects

A high-performance industrial textile cable project?

Our design office develops your product with you.

Our process

Submit your request using our contact form:

- Requirement

- End use

- Environment in which your product will be used

- Desired technical characteristics

- Desired length and diameter

- COUSIN® brand or white label

Our design office will then examine the feasibility of your request.

All technical and mechanical criteria are analyzed, including raw materials, assembly, construction, processing, finishing, and packaging.

If development is possible, the sales team will send you a quote and delivery time.

After approval of the quote and technical file, a prototype can be tested before being sent to you. We can have your product certified by the organization of your choice.

All our products undergo rigorous laboratory testing: breaking strength, impact strength, elongation, flexibility, knotability, sheath slippage, water shrinkage, etc.

All testing complies with the various ISO regulations and European standards in force.

Additional tests can be carried out on request.

Your request is ready for industrialization.

We are committed to meeting the deadline.

In military operations, hoisting ropes play a crucial role in mobility, logistics, and safety. Used for lifting, towing, evacuation, or extraction of equipment and personnel, they must meet strict requirements in terms of strength, reliability, and performance in extreme environments.

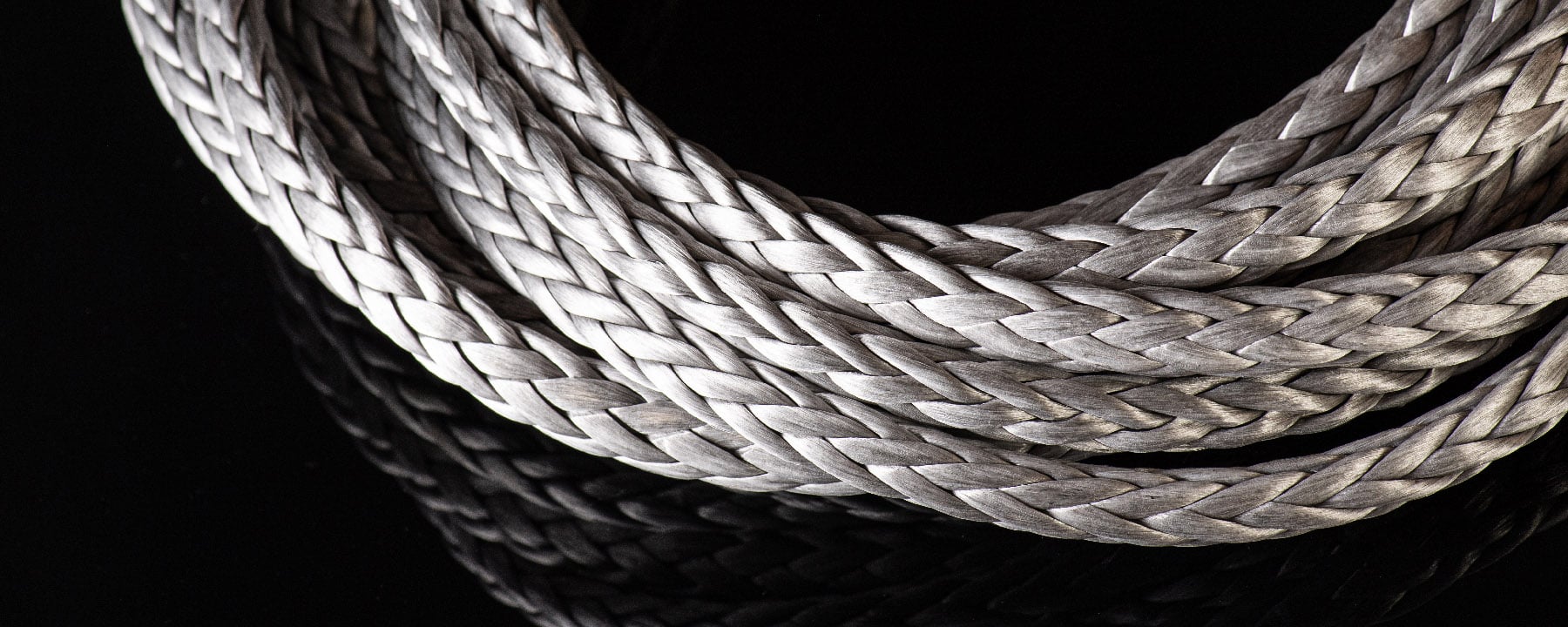

Hoisting ropes used by the armed forces are generally made from high-performance synthetic fibers such as Kevlar®, Dyneema®, or Technora®. These materials provide an exceptional strength-to-weight ratio, excellent resistance to abrasion, UV, chemicals, and heat all essential qualities in hostile operational contexts.

Diameters and lengths vary depending on the application, but these ropes are often designed to support loads of several tons while remaining light enough to be easily transported in the field. Some are also sheathed to enhance durability or incorporate signaling or nighttime visibility features (infrared, luminescent, etc.).

In operations, hoisting ropes can be used for: Extracting stuck or immobilized vehicles, evacuating injured personnel by helicopter (vertical hoisting), installing temporary bridges or crossing systems, setting up supply lines or rapid tactical deployment lines, securing heavy equipment during transport over rough terrain, in special forces, they are often integrated into assault kits to allow rapid deployment on facades, rooftops, or in mountainous areas.

Military ropes are subject to very strict qualification standards. They must meet criteria for breaking strength, dynamic and static tensile performance, as well as accelerated aging tests. Maintenance protocols are also implemented to ensure they are in proper condition before each mission.