Marine

Filter by usage

A project?

Cousin® develops your industrial projects

A high-performance industrial textile cable project?

Our design office develops your product with you.

Our process

Submit your request using our contact form:

- Requirement

- End use

- Environment in which your product will be used

- Desired technical characteristics

- Desired length and diameter

- COUSIN® brand or white label

Our design office will then examine the feasibility of your request.

All technical and mechanical criteria are analyzed, including raw materials, assembly, construction, processing, finishing, and packaging.

If development is possible, the sales team will send you a quote and delivery time.

After approval of the quote and technical file, a prototype can be tested before being sent to you. We can have your product certified by the organization of your choice.

All our products undergo rigorous laboratory testing: breaking strength, impact strength, elongation, flexibility, knotability, sheath slippage, water shrinkage, etc.

All testing complies with the various ISO regulations and European standards in force.

Additional tests can be carried out on request.

Your request is ready for industrialization.

We are committed to meeting the deadline.

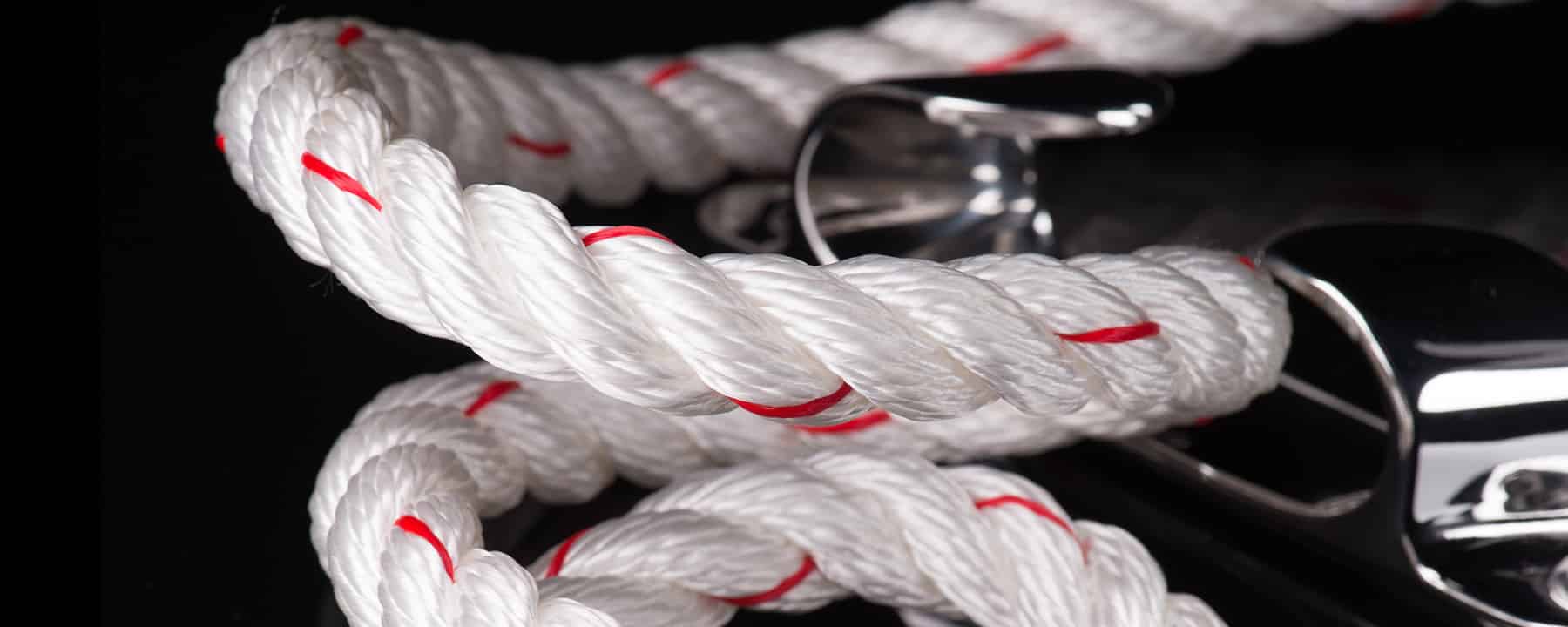

In the maritime industry, textile ropes play an essential role in a wide range of applications, from mooring and maneuvering to lifting, hauling, and rigging. Thanks to technological advances in synthetic fibers, modern ropes now offer performance comparable to or even superior to steel wire ropes, while being lighter, safer, and more durable.

The materials used, such as high-tenacity polyester, polyamide, Dyneema® (HMPE), Technora®, and aramid fibers, give the ropes exceptional breaking strength, high flexibility, low elongation, and excellent resistance to marine environments (UV, salt, humidity, abrasion, chemicals).

Textile ropes offer many advantages. They are lightweight, up to five times lighter than steel, making them easier to handle and reducing operator fatigue. They are flexible and easy to handle, easy to coil, can be spliced, are silent, and do not whip in the event of breakage. They are more durable, do not corrode, require little maintenance, and perform well in marine environments.

Used on commercial vessels, offshore platforms, fishing boats, sailboats, and in oceanography, textile ropes have become indispensable. They represent a modern, reliable, and high-performance solution that meets the growing demands for safety, efficiency, and sustainability in the maritime environment.